Kyokuto Holdings, Inc. Koushin Chemical Industry, Inc. Porihosu Chemical, Inc. JP | EN

Open smartphone menu

Kyokuto Holdings, Inc. Koushin Chemical Industry, Inc. Porihosu Chemical, Inc. JP | EN

Open smartphone menu

Business

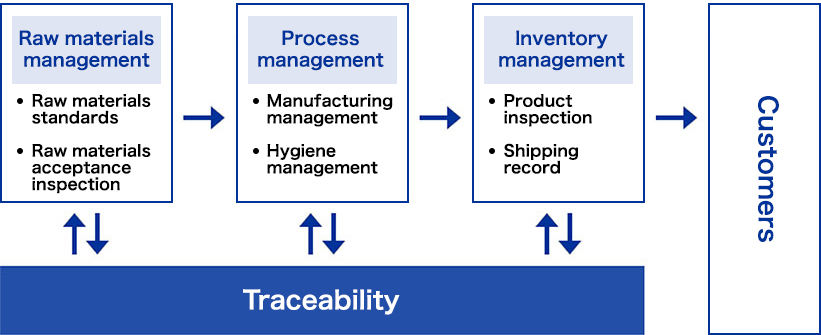

Our thorough quality management encompasses the entire process from the management of raw materials to the management of manufacturing processes and inventory, so that we are able to consistently provide safe and reliable products to customers.

We prioritize the provision of satisfactory high-quality products to customers in accordance with our basic policies, the customer-first principle and the environmental development and improvement. In line with our policies and with the goal of maintaining food safety and reliability, our work environment and hygiene environment are thoroughly managed and improved and a quality assurance system is in place, encompassing the entire process from the warehousing of raw materials to the delivery of products to customers. Furthermore, we keep records of the proper management of all raw materials, products, manufacturing equipment and apparatuses.

We require manufacturers to submit raw material specifications, conduct acceptance tests and control the quality of raw materials. Through the rigid management of manufacturing processes, we make products with stable quality. We also ensure the hygiene of our work environments and employees to keep our manufacturing practices safe. We conduct product testing to ensure that products meet the customer’s requirements and we also check process records to make a shipping judgment before delivering the product to customers. Each stage is traceable through cross-checking and the recording of raw material lots using our system.

A system has been introduced to centralize the management of an entire process from receiving an order to the warehousing of raw materials, manufacturing and product shipment. Based on the standards for GMP in food additives, we create a manual for each process and each employee responsibly puts his/her energy into manufacturing products under a rigid control system.

The process from the raw materials to the product is thoroughly managed in terms of production and quality and we issue product specifications, material certificates, product test sheets, safety data sheets (SDS) and other documents necessary for ensuring the safety and reliability of customers' products.

We built a quality assurance management system that is able to manage a variety of data for addressing and swiftly responding to requests from customers, including prompt action to address the amendment of food-related laws and the labeling of specified allergen-containing raw materials. In this way, we assure the quality and safety of our products.

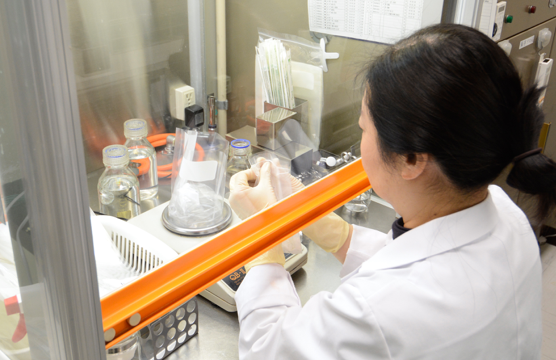

"The acceptance of raw materials involves a microorganism test (e.g. general viable bacteria, fungi, yeast, coliform group), a physicochemical test (e.g. viscosity, moisture, pH) and other tests whose results are used to check that raw materials comply with standards.

We conduct microorganism tests, allergen tests and other tests in accordance with the characteristics of products and how customers use them, to deliver products that meet customers’ product quality expectations. Using the latest production management system, we ensure that proper process management is implemented in the manufacturing of our products.

The use of the latest production management system makes it possible to specify the date of manufacturing, the raw materials, lot information and other related information and facilitate quick action in the event of, for example, a product recall or the suspension of shipments. Records are organized for each of the stages from the warehousing of raw materials to manufacturing and distribution, so that we can always be ready to trace any of the stages.

We manage the safety of products by, for example, preventing the intentional contamination of products with foreign matter. Surveillance cameras are placed within the premises to monitor workers and delivery trucks and record people's entrance into and exit from the factory. They monitor detergents and chemicals kept in locked spaces and ensure thorough inventory control.

Our work clothes are designed to prevent workers from bringing unnecessary objects or materials into workspaces and ensure that none of their body hair falls outside their clothes. We have clear rules on entering and exiting factories in a thorough effort to keep foreign matter from contacting products. During manufacturing, sieves, strainers, magnets and metal detectors are placed in the right locations for the process to prevent contamination with foreign matter. The sieves and other materials are washed and inspected every day and we check them and make a record of any damage or other abnormalities.

The factory has double doors to keep insects and foreign matters outside the facility. Raw materials have to go through an air shower so that they can be subsequently warehoused in a clean condition. Further, we have established an effective anti-insect and anti-rodent system in cooperation with specialized companies.

Our employees are encouraged to increase their awareness and participate in external and in-house workshops to maintain product quality. At in-house workshops, employees mainly learn about raw materials, products, food safety and food hygiene to enhance their knowledge and awareness. Off-the-job training(OFF-JT) is provided by an outside training company that we partner with. Each individual can freely choose from about 130 subjects to study the subjects they need to learn in light of their personal goals and work and strive to acquire broad knowledge.

FSSC 22000 (Food Safety System Certification) is a standard developed by the FSSC 22000 Foundation that provides guidelines for establishing a high-level food safety management system to ensure the delivery of safe food. This standard has been approved by the Global Food Safety Initiative (GFSI) as a food safety certification scheme.

Our Tokyo Factory has obtained certification for compliance with the requirements of FSSC 22000 Ver.6. By adhering to the following requirements based on FSSC 22000 Ver.6, we strive to enhance food safety and quality:

・Food Safety Management System (ISO 22000:2018)

・Prerequisite Programs (ISO/TS 22002-1:2009)

・Additional Requirements

Through these initiatives, led by our Food Safety Team, we are committed to reducing food safety risks, continuous improvement, and promoting legal compliance.

Moving forward, we will continue to earn your trust by delivering safe and high-quality food products.

Tokyo Factory

Registration Number:JSAF181

Saitama Factory

Registration Number:JSAF183

The GMP in food additives, or the voluntary standards on manufacturing management and quality management of food additives, is a voluntary standard set by the Japan Food Additives Association in pursuit of the continued development of quality management in the food additive industry. If your procedures for manufacturing and managing the quality of food additives satisfy the standards specified by the GMP in food additives, you can become certified by a third party, the Japan Food Additives Association.

Based on these standards, we check the quality and safety of the raw materials at all of the factories we own and properly manage and record the manufacturing processes. For each product, we use the management method specified for the product. In this way, we ensure product quality so that customers can feel secure about using our products.

Tokyo Factory

No.JAFAGMP-026-(6)

Fuchu Factory

No.JAFAGMP-122

Saitama Factory

No.JAFAGMP-123